Position: > Technical support > Common problem >

Class I: Low output laser (power less than 0.4 mW) will not exceed the MPE value for eyes and skin under any conditions, even after focusing through optical system. It can ensure the safety of design without special management. Typical applications such as laser pointer, CD player, CD-ROM equipment, geological exploration equipment and laboratory analysis equipment, short-distance communication and transmission, etc. (USE when the light source is exposed)

Class II: Visual laser with low output (power 0.4 mW-1 mW), the reaction time of closing eyes is 0.25 seconds,and the exposure calculated with this time cannot exceed the MPE value. Usually the laser below 1 mW will cause dizziness and unable to think. Close the eyes to protect it. It can not be said to be completely safe. Do not observe directly in the beam, nor use Class II laser to directly irradiate other people's eyes. Avoid using long-range equipment to observe Class II laser. Typical applications such as classroom demonstration, laser pointer, aiming equipment and range finder, etc.

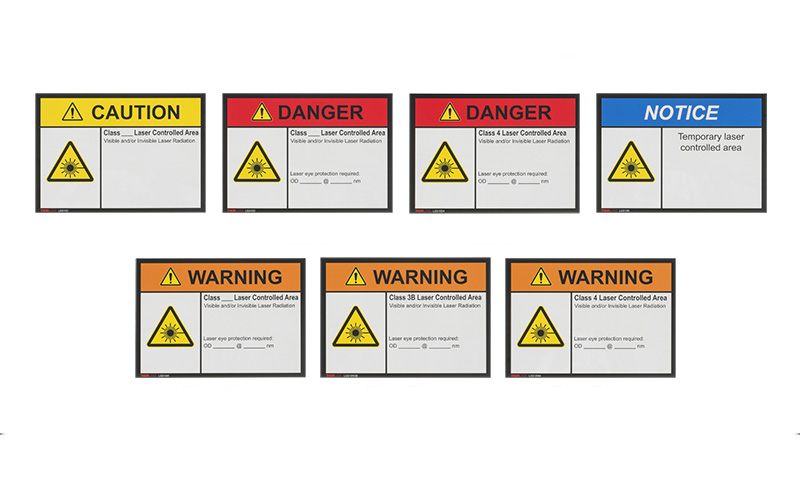

Class III: Middle output laser, if the beam directly into the eye, will cause damage, for some safety reasons, further divided into IIIA and IIIB.

Class IIIA is a continuous-wave laser with visible light output of 1-5mW. The energy density of the laser beam should not exceed 25W/m-m. The danger of observing IIIA laser with a long-range device may be increased. The typical application of IIIA has many similarities with Class II, such as laser pointer, laser scanner, etc.

Class III B CW laser is 5-500 mW. It is dangerous to observe directly in the beam. However, the minimum irradiation distance is 13 cm and the maximum irradiation time is less than 10 seconds. Typical applications for IIIB lasers include spectrometry and entertainment lighting performances.

ClassIV: High output CW laser (greater than 500 mW), higher than the third level, is dangerous to fire, and diffuse reflection is also dangerous. Typical applications include surgery, research, cutting, welding and micromachining. Level 1 is mainly used in laser pointer, CD player, CD-ROM equipment, geological exploration equipment and laboratory analytical instruments. (Use when the light source is exposed)Because the power is less than 0.4 mW. So it's harmless to the eyes. But because the distance of his illumination does not exceed 1 meter, it is impossible to apply to optical fiber temperature measurement. For some manufacturers, it is impossible to put forward a grade 1. In other words, his host is still in the other laser class 1, but it is definitely not a light source for temperature measurement.

Laser hazard

Laser radiation can cause damage to human eyes and skin, of which the former has the most serious consequences. Because the human eye transmits and absorbs different wavelength lasers, different wavelength lasers damage different parts of the human eye. The main eye injuries caused by laser irradiation are photokeratitis, corneal coagulation, carbonization and perforation, lens opacity, blindness of visual function"flash blindness", retinal coagulation, hemorrhage and burst. The main skin injuries caused by laser radiation are pigmentation, erythema and blisters. The degree of damage depends on the radiation dose, which is related to the output energy, working wavelength and working state of the second-hand laser cutter laser, of which energy is the most important factor. Not only direct light, but also reflected light and diffuse light are harmful to human body and working environment. When laser processing and laser treatment are carried out, harmful smoke, vapor and noise may be produced, which will cause radiation hazards to the environment. High power laser radiation can destroy some precision instruments and even cause fire. Laser radiation protection measures are based on laser safety protection standards. International standards mainly include International Electrotechnical Commission (IEC) standards and World Health Organization (WHO) standards.